-

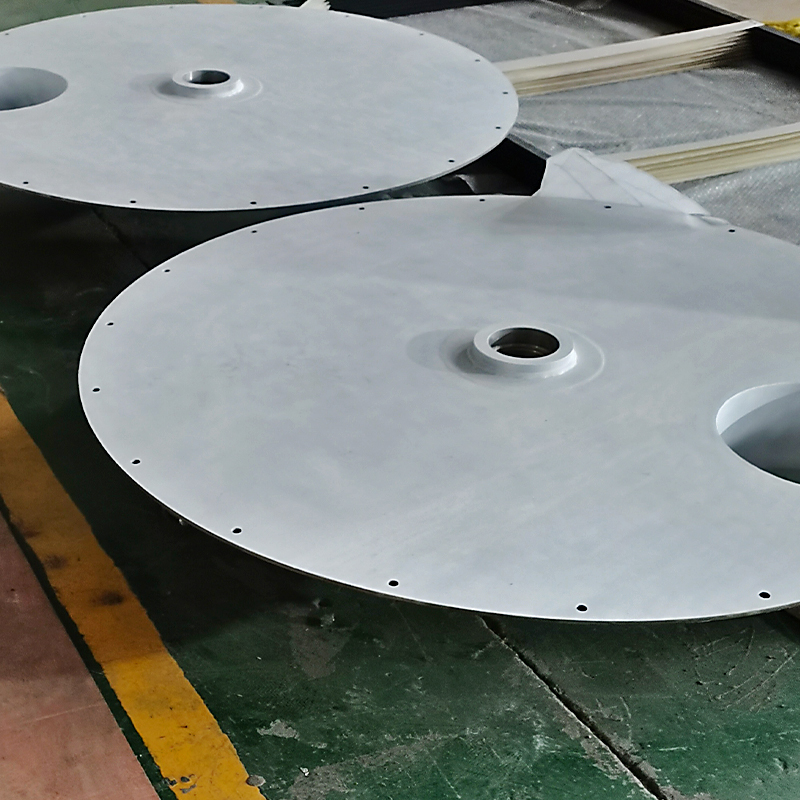

What is the application effect of Teflon spraying on lithium battery silo

Spraying Teflon on the lithium battery silo can significantly improve the performance of the silo, and has good effects in improving production efficiency, ensuring product quality and reducing maintenance costs, as follows: 1. improve production efficiency Promote material flow: the low friction coefficient of Teflon can make the flow of lithium battery materials in the silo more smooth,

Learn more -

What are the advantages of plasma sprayed alumina coating for lithium battery equipment

Lithium battery equipment plasma sprayed aluminum oxide coating has many advantages, mainly including the following points: 1. good insulation performance: the alumina coating has high resistivity, which can effectively prevent the current leakage inside the battery, avoid battery short circuit, and improve the safety and stability of the battery. This is very important for the reliable operation

Learn more -

What are the characteristics of ETFE anticorrosive coating sprayed on agitator

The agitator is sprayed with ETFE (ethylene tetrafluoroethylene copolymer) anti-corrosion coating, which has the following characteristics: 1. good corrosion resistance Strong acid and strong alkali environment: ETFE coating has good resistance to strong acid and strong alkali such as sulfuric acid, hydrochloric acid, nitric acid, sodium hydroxide, etc., can maintain stability in these co

Learn more -

What is spraying ECTFE for pharmaceutical three in one equipment

Spraying ECTFE on pharmaceutical three in one equipment is a surface coating technology, as follows: 1. Material properties of ECTFE: ECTFE is an ethylene chlorotrifluoroethylene copolymer, which is copolymerized with chlorofluoroethylene and trifluoroethylene. It has excellent chemical stability, can resist the erosion of strong acid, alkali, organic solvent and other chemical substances, and al

Learn more -

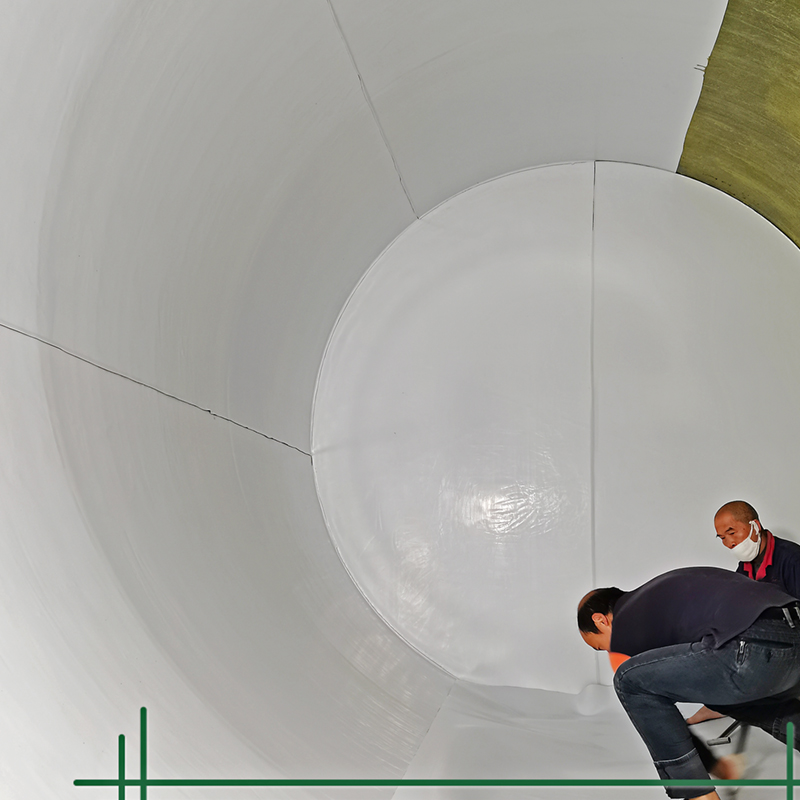

What are the applications of PTFE lining for chemical reaction vessels

The PTFE plate (polytetrafluoroethylene plate) lining of chemical reaction vessels has various applications in chemical reaction vessels due to its excellent chemical stability, high temperature resistance, low friction coefficient and other characteristics. The following are some main aspects: 1. Corrosion resistance protection Strong acid-base medium reaction: In chemical reactions involv

Learn more -

What's insulation capacity of ETFE anti corrosion coating sprayed on the head

The insulation performance of ETFE anti-corrosion coating sprayed on the head is very good, which is reflected in the following aspects: 1. High volume resistivity: At temperatures close to room temperature, ETFE has a volume resistivity of up to 1017 Ω· cm, which can meet general insulation requirements even under high temperature conditions. This means that it is difficult for current to pass t

Learn more -

What are the main uses of semiconductor duct spraying ECTFE

Semiconductor duct spraying ECTFE has the following main uses: 1. Corrosion prevention: During the semiconductor manufacturing process, a large amount of corrosive chemicals are used, such as strong acids such as sulfuric acid, hydrofluoric acid, nitric acid, as well as strong bases such as sodium hydroxide and potassium hydroxide. ECTFE has good chemical resistance, which can resist the erosion

Learn more -

What are the purposes of spraying PFA coating on chemical equipment

PFA (Fusible Polytetrafluoroethylene) is a high-performance fluorinated plastic. Spraying PFA coating on chemical equipment has multiple uses, as follows: 1. Corrosion prevention: Chemical production often comes into contact with various highly corrosive chemicals, such as sulfuric acid, hydrochloric acid, nitric acid, sodium hydroxide and other acid-base solutions. PFA coating has good chemical

Learn more -

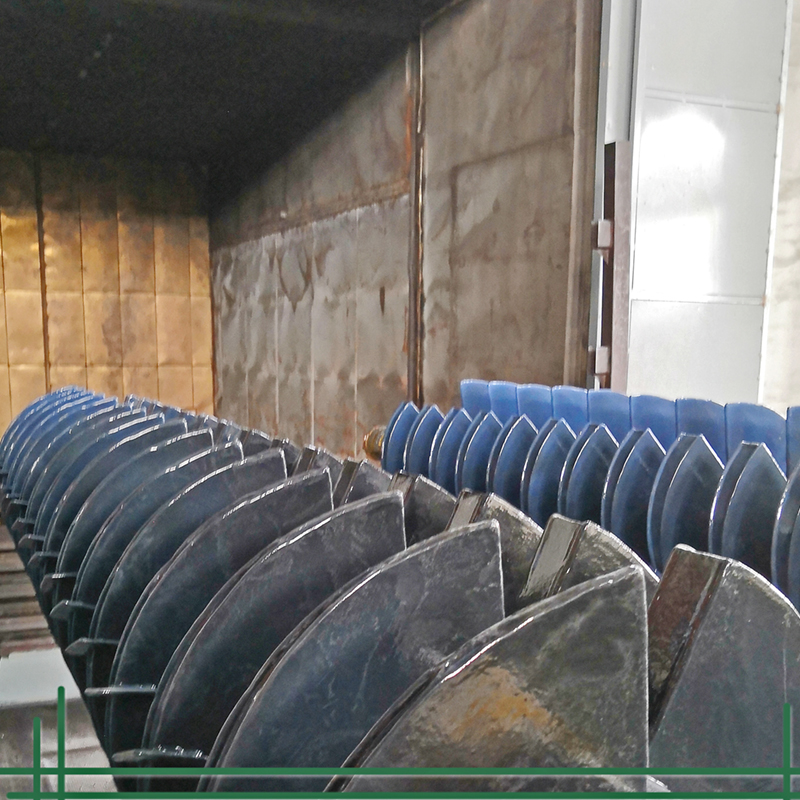

What are characteristics of vibrating screen frame sprayed with carbon tungsten

The vibrating screen frame sprayed with tungsten carbide has multiple characteristics, mainly reflected in high hardness and wear resistance, good corrosion resistance, thermal stability, etc. The following is a detailed introduction: 1. High hardness and wear resistance High hardness: Tungsten carbide itself has a high hardness, with a Mohs hardness of 9-9.5, second only to diamond. Spray

Learn more -

What are the precautions for spraying ECTFE on lithium battery equipment

When spraying ECTFE (ethylene trifluorochloroethylene copolymer) on lithium battery equipment, there are many key points to pay attention to, including surface treatment, spraying environment, material selection, etc. The following is a specific introduction: 1. Surface treatment Cleaning: The surface of the parts to be sprayed on lithium battery equipment must be cleaned to remove impuriti

Learn more

CN

CN EN

EN

Service hotline:

Service hotline:

Wechat number:

Wechat number:

National Service Hotline

National Service Hotline

Service hotline:0512-69211270

Service hotline:0512-69211270

Company address:1188 CUIZHOU Road, Lili Town, Wujiang District, Suzhou

Company address:1188 CUIZHOU Road, Lili Town, Wujiang District, Suzhou

contacts:Deng Guangcai 13912602396

contacts:Deng Guangcai 13912602396

contacts:Long Yanqiao 15995489385

contacts:Long Yanqiao 15995489385

Add wechat

Add wechat

Contact us

Contact us

Telephone consultation

Telephone consultation